The bulldozer undercarriage, as the "skeletal system" of the entire machine, directly impacts the return on equipment investment. Statistics show that improper maintenance leading to shortened bulldozer undercarriage life expectancy accounts for over 40% of total repair costs. This article provides an in-depth analysis of key factors affecting bulldozer undercarriage life expectancy and offers professional maintenance solutions.

I. Three Major Threats to Bulldozer Undercarriage Life Expectancy

1.Abrasive Wear

In harsh environments like mines and gravel pits, quartz sand and other hard particles accelerate wear on track shoes and rollers, reducing bulldozer undercarriage life expectancy by 30%-50%.

2.Corrosive Environments

Coastal salt spray or chemical plant acids/bases corrode track links, decreasing bulldozer undercarriage life expectancy to just 60% of normal conditions.

3.Improper Operation

Frequent sharp turns and overload operations cause abnormal track stretching, the primary human factor in reducing bulldozer undercarriage life expectancy.

II. 7 Golden Rules to Extend Bulldozer Undercarriage Life Expectancy

1.Daily Track Tension Checks

Maintain manufacturer-recommended 10-15mm sag. Over-tightening can reduce bulldozer undercarriage life expectancy by 2,000 operating hours.

2.Regular Track Reversal

Swap left/right tracks every 500 hours. Balanced wear can increase bulldozer undercarriage life expectancy by ~25%.

3.Use OEM Grease

Substandard grease causes roller bearings to fail prematurely. Certified lubricants extend bulldozer undercarriage life expectancy beyond 8,000 hours.

4.Prompt Debris Removal

Clear rocks from track gaps post-operation to prevent "abrasive effect" damage.

5.Wet Season Protection

Pressure-wash and apply anti-rust spray after working in humid conditions.

6.Avoid Side Slope Work

Operating on slopes >15° causes uneven track wear. Proper route planning preserves bulldozer undercarriage life expectancy.

7.Professional Rebuilding

At 30% wear, laser-clad track shoe repairs save 60% versus replacement.

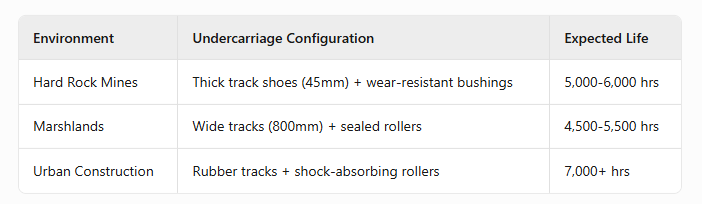

III. Site-Specific Solutions: Optimizing Bulldozer Undercarriage Life Expectancy

IV. Hengwang Group HW32D Bulldozer: The Undercarriage Durability Benchmark

Setting new industry standards for bulldozer undercarriage life expectancy:

Reinforced Structure: Cr-Mo alloy steel track links with 35% higher tensile strength.

Smart Lubrication: Auto-monitoring track joint lubrication reduces downtime.

Modular Design: Individual roller group replacement cuts repair costs by 40%.

Ideal for harsh long-term operations, third-party tests confirm the HW32D's bulldozer undercarriage life expectancy exceeds competitors by 18%-22% in comparable conditions. Paired with a Cummins 257kW low-consumption engine, it achieves perfect balance between performance and durability.

Road Leveling Bulldozer: The Core Guarantee for Efficient Road Construction

Road Leveling Bulldozer: The Core Guarantee for Efficient Road Construction

Off-Road Forklifts_ A Powerful Assistant for Complex Field Operations

Off-Road Forklifts_ A Powerful Assistant for Complex Field Operations

High-Load Off-Road Forklift: A Powerful Tool for Heavy-Duty Operations in Complex Environments

High-Load Off-Road Forklift: A Powerful Tool for Heavy-Duty Operations in Complex Environments